Hardfacing

Hardfacing is the application of a hard, wear-resistant material to the surface of a component by welding, thermal spraying, or allied welding processes to reduce wear or loss of material by abrasion, impact, erosion, galling, and cavitation. Hardfacing materials include a wide variety of alloys, carbides, and iron-, nickel-, or cobalt-base.

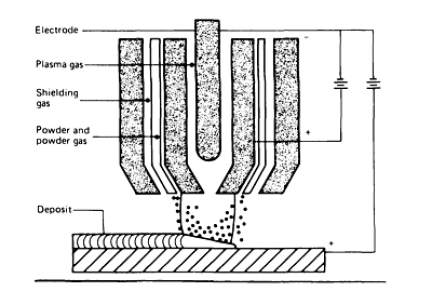

Plasma Transferred Arc - PTA

Plasma transferred arc surfacing is a welding process in which the powder is introduced into a combined arc/plasma stream to form a molten pool on the workpiece. The resulting deposit is homogeneous and dense, with excellent metallurgical bonding with the base metal (workpiece). Plasmapazhouh Pars Company has initiated providing hard coating services by PTA automatic line.

The advantages of PTA Welding, compared to traditional hardfacing methods can be mentioned as follows:

- high deposition rate;

- small heat-affected zone;

- low dilution rate with base material;

Some PTA Welding applications:

- screws of extruders;

- rollers and lamination;

- agricultural equipment;

- valves and seats;

- industrial knives and blades;

- mining equipment

- forging dies;